After 2015 when UL introduced updates to safety standards for fuel nozzles, many nozzles had a hold-open clip on them but were not pressure-activated. But when UL 2586 took effect, those nozzles were not in compliance with safety standards. Some think the change affected 30 percent of fueling applications.

"When UL introduced safety standard 2586, if you didn't have a pressure-activated nozzle, you could not have a hold open clip," said Jerry Mahn, Husky Corporation Mechanical Engineer.

Mahn was on the Husky engineering team that set out to develop a solution to that problem for the many affected retail, farm and commercial, and high volume applications. They came up with what Husky calls internally its 3-in-1 line of fuel nozzles. Husky modified one of its established nozzle platforms with new components, new castings and a pressure-activation feature that permits the use of hold-open clips in order to comply with UL 2586.

"It's a lot safer. You cannot open the main poppet valve until there's pressure supplied from the dispenser. That's a big deal for safety at retail sites," Mahn said. "And now farmers with this nozzle can use the hold-open clip, put the nozzle in the tank and walk away rather than standing there until the tank is full."

The nozzles are available in these categories:

- 1AS – Pressure activated, automatic shut-off nozzle for full-service and self-service stations

- 1GSS – Pressure activated, automatic shut-off nozzle for farm, 12V skid tanks, and commercial applications with multiple users

- Note: Farm and commercial applications that involve only one user do not require UL-certified nozzles. Contact Husky for more information and pricing.

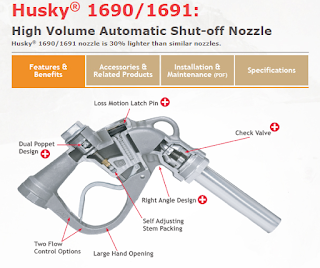

- 1HSS – Pressure activated, automatic shut-off nozzle for truck and high-volume applications

No comments:

Post a Comment